How To Make A Slide Whistle

![]()

In this TV, nosotros volition be creating a slide whistle.

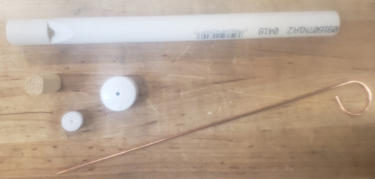

Bill of Materials

- ½" PVC

- ½" PVC cap with hole in end

- ½" dowel

- ½" delrin plug

- Welding rod

CAD

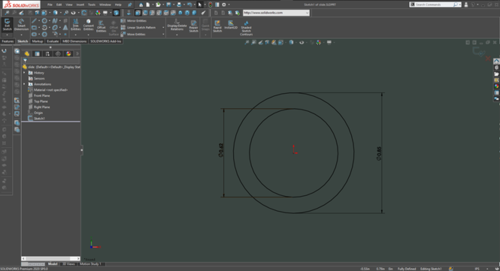

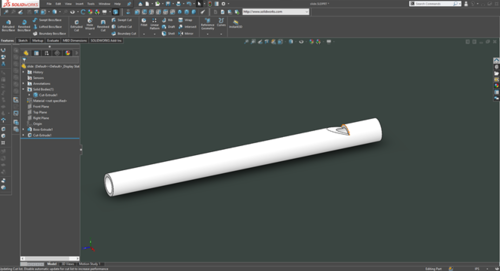

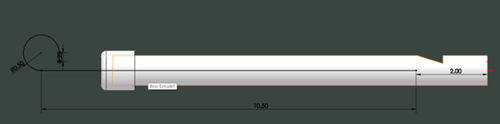

The trunk of the whistle is made from ½ inch schedule 40 PVC piping.

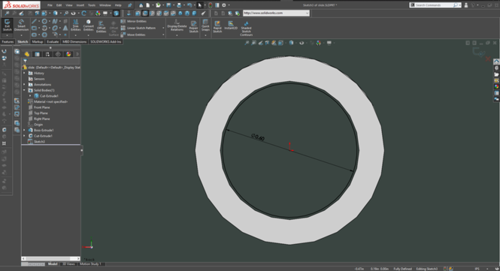

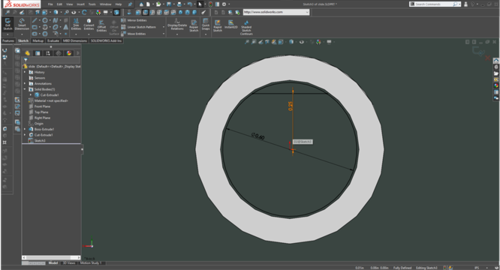

To model this, first create a sketch on the front plane. In this sketch, describe 2 circles. The outer diameter of the pipe is 0.85", and the inner diameter is 0.62". Make certain the circles are centered on the origin.

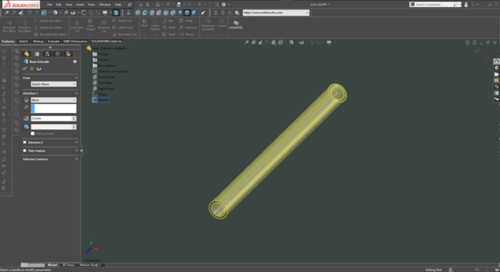

So, extrude the profile to create the pipe. A length of 10.5 inches works well.

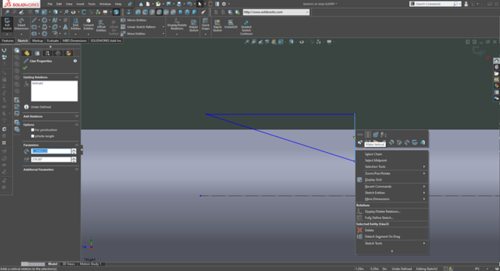

Next up, we need to create the notch that allows the whistle to produce audio. Start a new sketch on the right plane. In order to run across the plane face up on, hitting space, and click the side of the cube that is parallel to the sketch.

On this plane, first describe a line from the origin back into the pipe. Right click on it and set information technology to be construction geometry. This means that Solidworks volition ignore the line when making the cutting; only we tin still measure off of information technology.

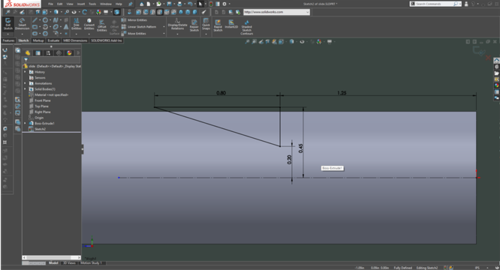

Adjacent, describe a triangle using the line tool. The top line should be horizontal, and the vertical line should be, well, vertical.

Lock these lines to being horizontal and vertical by right clicking on them, and clicking either make horizontal or make vertical.

Side by side, insert dimensions to ascertain the location and size of the cut. It should be i.25" from the get-go of the pipe, and 0.2" from the center line.

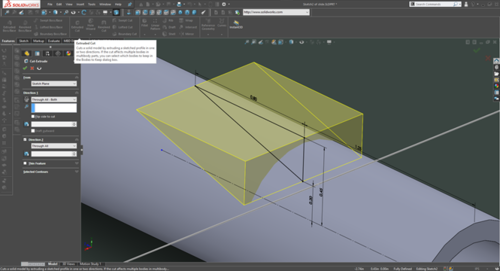

Once all dimensions are inserted, the triangle'southward lines should all exist black. This indicates that the sketch is fully defined. We tin now use the extrude cut tool to turn the sketch into the notch.

In the direction box, select the ```Through All – Both ``` choice. This cuts from both sides of the sketch.

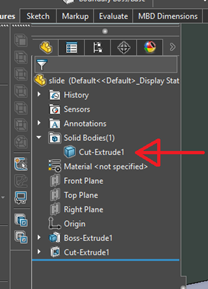

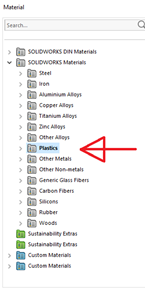

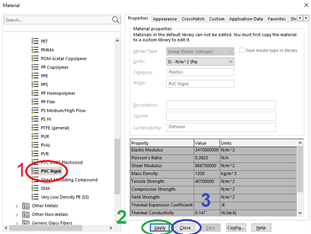

And there we get! Lastly, permit's prepare the material of the object to PVC. Do this by right clicking on the body in the characteristic tree and clicking on "material" > "edit material". In the window that opens, click on the "plastics" folder. In this folder, observe "PVC Rigid". Click on it, and then click apply, then close.

The pipe should now exist white, merely like real PVC!

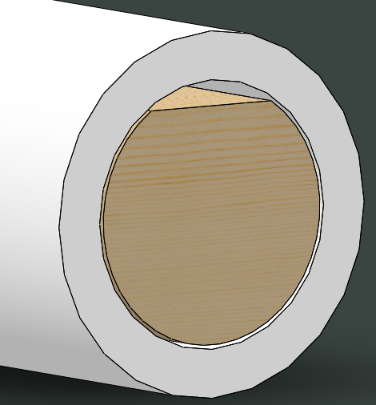

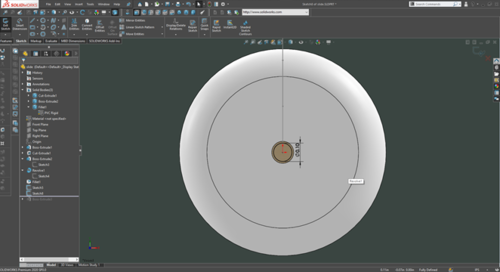

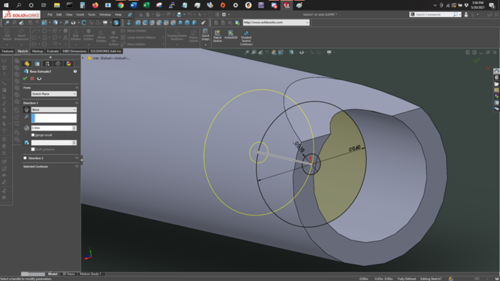

Next, we need to model the wooden plug that sits inside the end of the whistle.

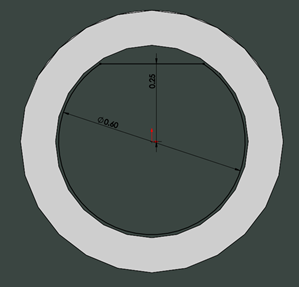

Click on sketch to create a new sketch and place information technology on the finish of the whistle. Draw a circle just a footling smaller than the inner diameter of the PVC, and set information technology's bore to 0.6".

To create the flat top of the peg, depict a line beyond the top of the circle. Place both the starting time and the finish of the line on the circle. Next fix the line to horizontal, as shown above. Add a dimension from the origin to the line and prepare it to 0.25". All lines in the sketch should exist black.

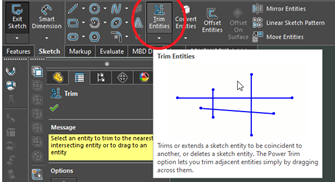

Side by side, remove the bend above the line using the "trim entities" tool. Click the tool, and click the summit of the circle. That part of the circle should now be gone, and the sketch should be a single loop of lines.

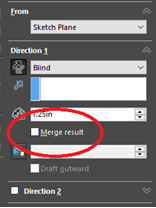

Side by side, we tin extrude the sketch to grade the plug. Click on extrude, and set the length to i.25". Every bit this is a divide part, uncheck "merge effect" in the extrude options. This causes the extrude to create a split body, which we tin fix to be a dissimilar textile.

We take the plug! At this point, the plug is the default grey. Permit's set that. Nether the bodies folder in the characteristic tree, there should now be 2 bodies. The 2nd ane is our plug. Using the same process as before, set it's material to exist wood. There is a woods folder just like a plastics folder. Open information technology and chose pine.

At present nosotros have a wooden plug!

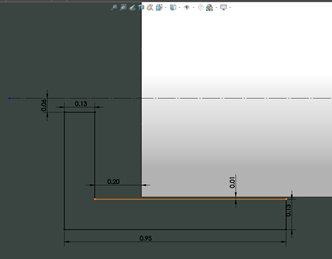

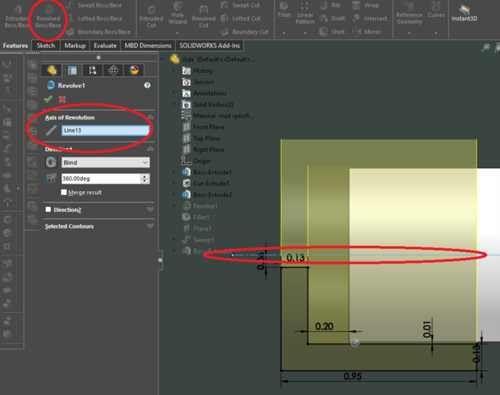

Next, let's model the cap on the terminate.

Create a sketch on the right plane, and go parallel to it (hitting space, and click the cube'southward side). Draw the shape of the cap, using the dimensions below. The construction line (dashed) in the middle is connected to the origin at the other end of the pipage and is horizontal. Information technology'due south needed in the next step, so remember to include it.

To turn this into the cap, a revolve is used. This spins the sketch around an axis to create a solid. In this instance, the construction line is that axis. Select the revolve selection, and if it does not automatically find the center line (it did for me), click on the "axis of revolution" box and then select the line.

To round off the edges of the cap, permit's add a filet. Filets are an amazingly simple way to plow sharp corners into rounded edges. to add ane, showtime click on the fillet tool, and then select the edge that yous want to round off.

And nosotros have a cap!

In one case once more, it's a new body, and then set it's material to PVC just like the pipe body

The last thing to make is the slider that makes this a slide whistle.

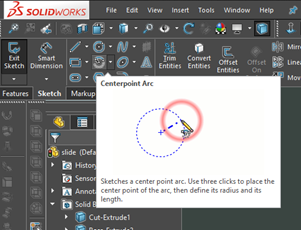

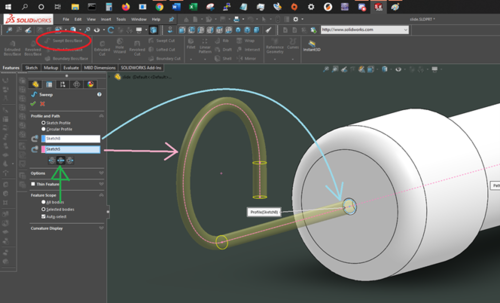

Get-go by creating a sketch on the correct plane. On the sketch, depict a line that represents the path that the rod will follow. To make the bend on the terminate, utilize the centerpoint arc tool.

Next, nosotros need to draw the outer shape of the rod. Create another sketch on the stop of the cap and describe a 0.ane" circle on the origin. Exit this sketch likewise.

Next, a sweep is created using the two previous sketches. Select the sweep tool, select the 2 sketches, and select the Bidirectional option (green).

This creates a rod with a bend at the end.

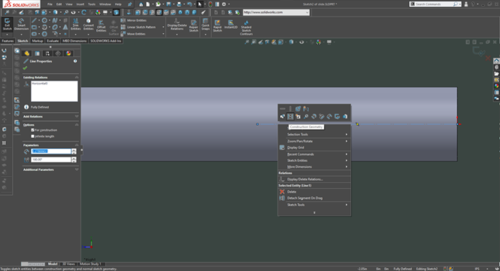

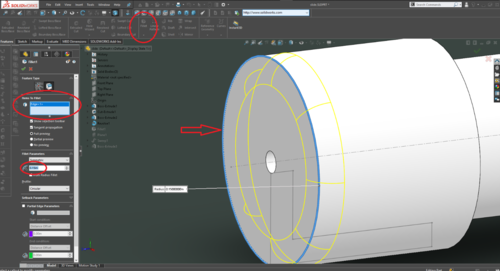

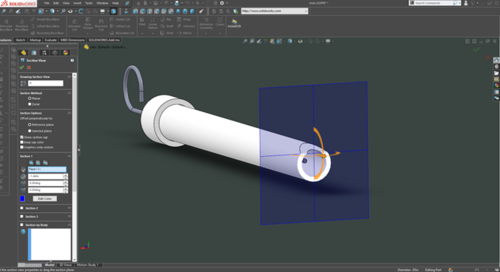

Next, we demand to model the plastic plug that is attached to the end of the wire. Equally information technology is hidden inside the master trunk of the role, nosotros need to practice something to go access to it. Solidworks has a tool that makes this easy, called section view. To utilize it, click on the icon shown below:

This lets y'all drib a plane onto the part, and everything on the close side will be hidden. Don't worry, information technology's not gone. But click the icon again to become dorsum to the full part. For this part, cutting off the cease of the pipe at the mouthpiece end.

And so, create a new sketch on the end of the wire. Draw 2 circles, one the size of the wire, and the other a little smaller than the inner diameter of the pipe. Extrude this sketch to a length of ½". Make sure that "merge result" is not checked.

And you're done with the cad!

Make the parts

- Now, it'due south time to build information technology. Materials required:

- ½" PVC

- ½" PVC cap with hole in stop

- ½" dowel

- ½" delrin plug

- Welding rod

Showtime, the notch in the pipe needs to exist cut. It is important that this notch not be to large or to deep, as it will negatively effect the devices ability to make sound. Start by using a hacksaw to cut a small notch vertically into the pipe. Mount the pipe in the rubber vice clamps and cut just until through the wall of the piping.

Next, cut in at an angle to form the notch. To showtime the cut, it is helpful to have a couple strokes vertically, and and so cut in at an angle from that starting indicate.

Cut down to the vertical notch, removing the plastic triangle. The resulting notch will be rough, and then adjacent, use a wide file to smoothen out the surface. Once the surface is shine, remove the burs left on the inside of the cut with the deburring tool. Exist careful not to remove too much fabric, as the tip of the notch needs to be sparse and sharp to produce good sound.

Next, we demand to bend the loop on the end of the wire rod. To do this, we will use the wire bender, which has a tutorial *here*. Utilise the ½" center peg and clench the wire confronting it as shown beneath.

Once the wire is clamped in place, use the bough to bend the wire effectually the heart peg, forming a loop.

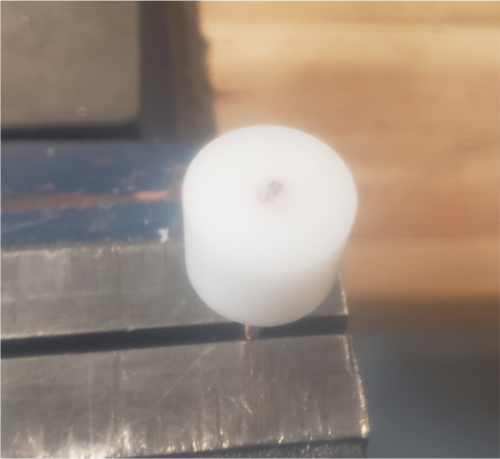

The last part to make before assembly is the wooden peg. The outer diameter should match the pipe's inner diameter, but the apartment side needs to be created. To practise this, simply sand the peg against sand paper until a suitable flat surface is created.

Assembly

First, slide the cap onto the wire rod. Make certain it is pointing the correct direction. Then, clench the rod in the vice, with about ¾" protruding to a higher place information technology. Take the delrin cylinder, and using a mallet, gently pound it onto the wire. Terminate once the wire is fully through the cylinder.

Lastly, slide the slide assembly into the pipe, and insert the wooden peg into the opposite cease.

And you're washed!

Source: https://maker-hub.georgefox.edu/wiki/Slide_Whistle

0 Response to "How To Make A Slide Whistle"

Post a Comment